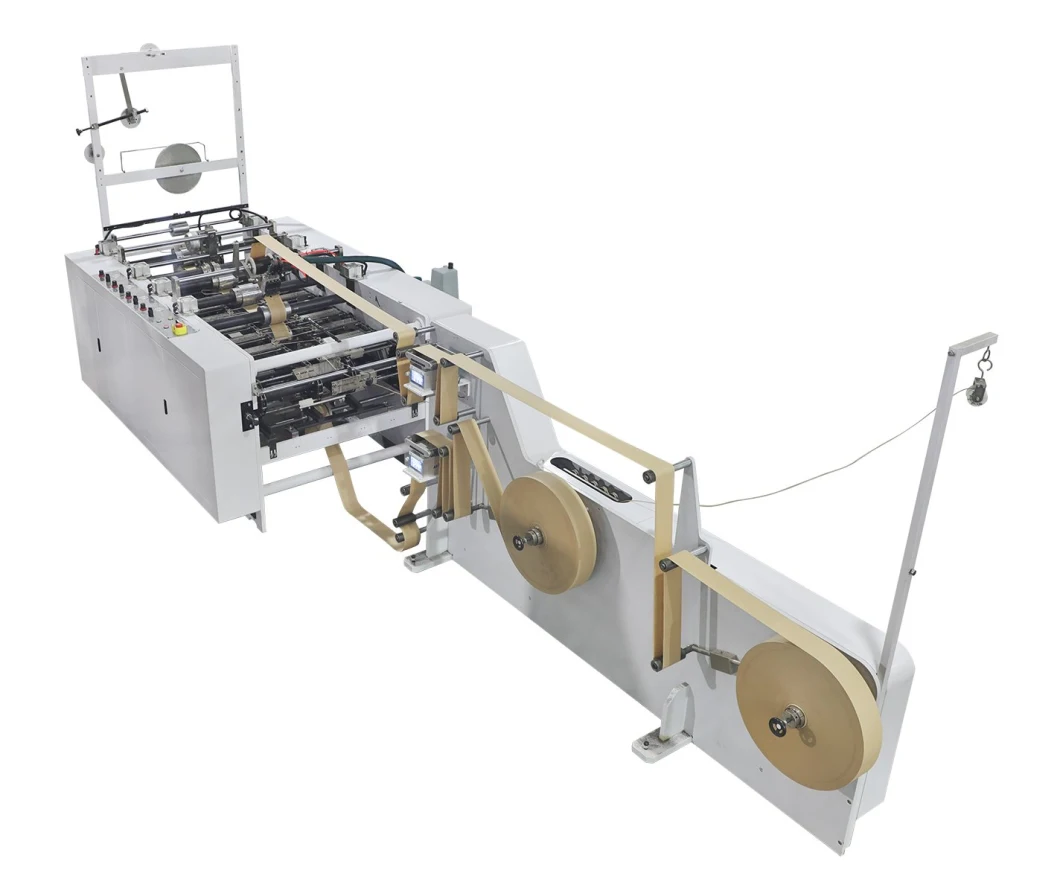

Fully Automatic Square Bottom Paper Bag Making Machine with Twisted Handle Inline

Overview Package size per unit product 20.00cm * 20.00cm * 10.00cm Gross weight per unit product 5.000kg Fully Automatic

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | XKFD-330T |

| Bag Type | Shopping Bag |

| Characteristic | Automatic Glue |

| Computerized | Computerized |

| Speed | High |

| Width | 220-330 |

| Size and Shape | 12600*5880*3150 |

| Long | 225-370 |

| Weight | 13500kg |

| Material | Paper |

| Usage | Shopping Bag, Leisure Food Bag, Bread Bags, Fruit Bag |

| After-Sales Service Provided | Field Installation, Commissioning and Training |

| Automatic | Computerlized |

| Servo Motor | Mitsubishi |

| Keywords | Paper Bag Making Machine |

| PLC | Mitsubishi |

| Function | Paper Bag Producing |

| Bag Width | 220-330mm |

| Bag Length | 225-370mm |

| Application | Food Packaging, Shopping Bag |

| Brand | Xinke |

| Patch Paper Roll Width | 80-100mm |

| Patch Paper Thickness | 100-135GSM |

| Roll Paper Diameter | 1200mm |

| Paper Thickness | 60-160GSM |

| Handle Height | 100mm |

| Transport Package | Stretch Film Package and Container |

| Specification | speed: 30-120pcs/min |

| Trademark | Xinke |

| Origin | China |

| HS Code | 8441200000 |

| Production Capacity | 200sets/Year |

Packaging & Delivery

Package size per unit product 20.00cm * 20.00cm * 10.00cm Gross weight per unit product 5.000kgProduct Description

Fully Automatic High Speed Square Bottom Paper Bag Making Machine with Twisted Handle InlineProduct Description

Fully automatic square bottom paper bag machine is designed for the production of paper bags with twisted handles. It is suitable for mass production of shopping bags in industries such as food and clothing. The one-line process consists of twisted handles making from paper rolls and twisted rope, delivery of handles to paste unit, pre-cutting of paper on position of rope, patch position gluing, handle pasting, and paper bag making. The paper bag making process consists of side gluing, tube forming, cutting, creasing, bottom gluing, bottom forming and bag delivery. This machine adopts Japan imported high-speed motion controller (CPU), which controls the operation of servo through high-speed bus to ensure stable movement and smooth motion curve. It is the automatic square bottom paper bag equipment with handles inline preferred by the majority of printing and packaging manufacturers.

Product Parameters

| Model | XKFD-330T | XKFD-450T | XKFD-540T |

| Cutting length | 270-530mm | 270-530mm | 400-770mm |

| Cutting length(Ful) | 270-430mm | 270-430mm | 400-670mm |

| Bag width | 150-330mm | 220-450mm | 250-540mm |

| Bag width(Ful) | 220-330mm | 290-450mm | 320-540mm |

| Bag Length | 225-470 | 225-470 | 320-680 |

| Bag Length(Ful) | 225-370mm | 225-370mm | 320-580mm |

| Bottom width | 60-180mm | 80-220mm | 120-260mm |

| Paper Thickness | 60-160g/m2 | 80-160g/m2 | 90-160g/m2 |

| Paper Thickness(Ful) | 60-160g/m2 | 80-160g/m2 | 90-160/m2 |

| Paper roll width | 440-1050mm | 630-1370mm | 770-1630mm |

| Paper roll width(Ful) | 585-1050mm | 770-1370mm | 910-1630mm |

| Roll paper diameter | φ1200mm | φ1200mm | φ1200mm |

| Patch paper thickness | 100-135g/m2 | 100-135g/m2 | 100-135g/m" |

| Machine Speed | 30-200bags/min | 30-200bags/min | 30-200bags/min |

| Power Supply | 380V 3Phase 35KW | 380V 3Phase 35KW | 380V3Phase 39KW |

| Machine weight | 12000kg | 13500kg | 15000kg |

| Machine size | 14000x5800x2400mm | 14000x6000x2400mm | 14000x6500x2400mm |

Machine Details

The twisted handle inline device: produce the twisted rope handle with the paper bags directly.The bag forming part in the paper bag machine.The finished bag delivery part:Horizonal delivery or bucket delivery way for choose.Use Taiwan WEINVIEW touch screen human-computer interface, making the machine easy to operate and control.Delivery The HandleSample Bags

Producing Process

Related Products

Company Profile

Xinke Machinery was founded in 2000, it has been 20 years since the present, it has a rapidly developing during this period become as one of China outstanding packaging machinery manufacturers. Our success key point is professional technical team has more than 20 years experience in paper bag machinery manufacturer, we can design and produce the paper bag machine by ourselves to keep the machines up to date.

Cooperating with famous brand, like Sick, Mitsubishi and so on. We provide customers a 360˚ after-service, from start-up and installation, to preventive maintenance. Thus, the quality of your productions can be promise with high quality equipment, warranty and post-warranty service.

We had export and import license, CE for European Market and ISO for local market, we export to more over 1000 companies in 100 countries in the world.

We can be your trusted partner, Xinke Machinery

After Sales Service

1.Quality Commitment: one year guarranty,Lifelong maintenance, Vulnerable parts are provided free of charge within 12 months.2. After-sales Service: 24hours online to help customer solve problem.3. Operation Guide: after the customer receives the goods, the engineer will guide the installation throughout.4. Machine Parts: all machine parts are imported from famous imported brands, which are convenient for customers to repair and buy by themselves.

FAQ

| Q: Where are your factories located? May I have a visit ? A: First of all,warmly welcome! Our factory located in Ruian city, Zhejiang Province Q: Do you have machines in stock to sell? A: No,we according to customers' requirements to manufacture the machine. Q: How is the quality of your machine? A: We have 20 years experience of manufacture the machine, choose the famous brand parts to produce the machine, the quality can be guaranteed. Q: What about the lead time for mass production? A: Honestly, it depends on the order quantity and the machine type. Normally, the produce period is 35-90days. Q: What is your terms of delivery? A: We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you. |

Related Products

-

![Price Fully Automatic with Ultrasonic Online Handle Sealing Non Woven Fabric Box Bag Shopping Bag T Shirt Bag D Cut Vest Bag Stringing Shoe Bag Making Machine]()

Price Fully Automatic with Ultrasonic Online Handle Sealing Non Woven Fabric Box Bag Shopping Bag T Shirt Bag D Cut Vest Bag Stringing Shoe Bag Making Machine

-

![2021 Best Selling New Paper Cup and Plate Machine/Good Machine for Manufacturing Paper Cups]()

2021 Best Selling New Paper Cup and Plate Machine/Good Machine for Manufacturing Paper Cups

-

![Plastic PE/PP/LDPE/LLDPE/BOPP/HDPE/Pet/Bottle/Laminated/Film/Woven Bag/Non Woven/Foil/ Crushing, Washing, Drying Machine Plastic Recycling Machine]()

Plastic PE/PP/LDPE/LLDPE/BOPP/HDPE/Pet/Bottle/Laminated/Film/Woven Bag/Non Woven/Foil/ Crushing, Washing, Drying Machine Plastic Recycling Machine

-

![Hamburger/Burger/Lunch Paper Box, Kfc, Macdonald′s Fast Food/Pizza Box, Paper Tray Bag Cup Plate Making/Forming Machine, Paper Carton Box Erecting Machine]()

Hamburger/Burger/Lunch Paper Box, Kfc, Macdonald′s Fast Food/Pizza Box, Paper Tray Bag Cup Plate Making/Forming Machine, Paper Carton Box Erecting Machine