Side Sealing Bag Making Machine

Overview Product Description It is Servo motor driving, computer controlling. Direct digit input. Touch screen operation

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | SX-600 |

| Speed | Medium |

| Continuous-Rolled | No |

| Sealing & Cutting | Heat-Sealing Heat-Cutting |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Side Sealing Bag Making Machine |

| Control System | Servo System |

| Main Motor | 1.5kw |

| Machine Weight | 1150kg |

| Transport Package | Wooden Package and by Ship |

| Specification | 4.9CBM |

| Trademark | shunxiang machinery |

| Origin | China |

| Production Capacity | 20set/Month |

Product Description

It is Servo motor driving, computer controlling. Direct digit input. Touch screen operation. Photocell for color registration and edge position controlling. Never have any serious problem.

It has functions of automatic tape putting, edge slitting, bags fold, hole punching, etc. Automatic counting, Dot sealing is available. Automatic constant temperature controlling, Strong and stable sealing.

Applications:

It is mainly for hot side sealing bags made of BOPP, OPP, PP, PE and other printed and none printed films. Produce express bags. Single-layer and double-lane is available. Many types and models. Special requirements always are available.

Max.machine speed:250 cuts/min. Bag length, width & speed are controlled by digit. Error: +/-0.1mm.

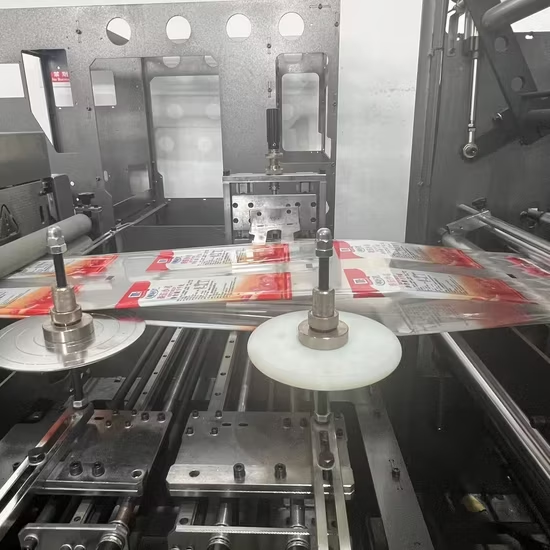

Detailed Photos

Product Parameters

Main Technical parameters

| Model | SX-500 | SX-600 | SX-800 | SX-1000 |

| Bag making width (mm) | 25-450mm | 45-550mm | 60-700mm | 150-900mm |

| Max. length (mm) | 600mm | 600mm | 600mm | 600mm |

| Film thickness (mm) | 0.01-0.2mm | 0.01-0.2mm | 0.01-0.2mm | 0.01-0.2mm |

| Length Error (mm) | <0.5mm | <0.5mm | <0.5mm | <0.5mm |

| Max. production (Pcs/min) | 100-250cut/min | 100-250cut/min | 80-200cut/min | 80-150cut.min |

| Drive Motor (kw) | 1.5kw | 2.2 kw | 2.2kw | 2.2kw |

| servo motor | 1,5kw | 1.5kw | 1.5kw | 1.5kw |

| Heating power (kw) | 1.5kw | 2kw | 3kw | 4kw |

| TOTAL power | 3kw | 4.5kw | 6kw | 8kw |

| Power Source: | 220 AC+_10% 50HZ | 220 AC+_10% 50HZ | 220 AC+_10% 50HZ | 220 AC+_10% 50HZ |

| Machine's size | 3000mm*1050mm*1710mm | 4100mm*1270mm*1710mm | 4200mm*1450mm*1710mm | 4500mm*1890mm*1800mm |

| Machine weight (kg) | 1100kg | 1300kg | 1680kg | 2200kg |

Packaging & Shipping

Company Profile

Dongguan Shunxiang Plastic machinery Co.Ltd, Located in Changping town, Dongguan City, near to Guangzhou and Shenzhen city, is a specialized manufacturer of Plastic machinery which include Stretch film extrusion machine, PE/PO film blowing machine, PP film blowing machine, flexography/gravure printing machine, all kinds of bag making machine, waste plastic recycling machine, EPE foam extrusion producing line, EPE Foam further processing equipment, high-speed gravure printing machine,High-speed dry laminating machine, and so on. we enjoy convenient access to major transportation networks.

Our Advantages

Our company has such advanced facilities . Our annual production capacity is More than 300 sets. Holding a trade license,Owning to expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. we export products to More than 200 countries and regions in South America,Southeast Asia, Europe and Africa. Our products gain wide praise at home and abroad. Our company has won ISO9001, CE certificates. Strict quality control covers every procedure, from material sourcing and processing through to testing and packing. Our tenet is"Brand is created by quality, market is gained by service". We warmly welcome customers at home and abroad to establish cooperation and create a bright future together with us.

After Sales Service

We have three way to service:

1.When machine arrived buyer factory, we will arrange engineer to buyer factory for installation and testing machine , and give customer some train, in common time range is 7-15days. Any machine's problem, our engineer will give a train.2. When engineer go back, so machine have some problem happened, at the first, we will have meeting by video chat,we will tell customer how to solve? If it is no problem to solve them, so all is good. If it can not , we will send engineer to buyer's factory again. or we will invite some other maintenance personnel in buyer's country to supply help(some countries have our customer and using our machine in there) 3.If just need to change some spare parts , we will send DHL to buyer and guide to change, it is free to buyer(under warrant).

FAQ

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and weprovide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, L/C paying methods. For those orders less than 500USD, we accept Trade Assurance to pay.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.