Good Quality Automatic HDPE LDPE PE Bag Forming Machine Plastic Bag/Shopping Bag Making Machine Price

Overview Product Description Fully Automatic Soft Loop Handle Bag Making Machine This machine has 2 functions (soft loop

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | DC-800LP |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Plastic Bag Making Machine |

| Bag Width | 250-600mm |

| Top-Folding Edge | 50-75mm |

| Soft Loop Handle Bag | 60PCS/Min |

| After-Sales Service Provided | Online Support |

| Video Outgoing-Inspection | Provided |

| Die Cut Handle Bag | 80PCS/Min |

| Bottom Gusset | 20-70mm |

| Height of Bag | 250-750mm |

| Total Power | 10kw |

| Machine Weight | 3200kg |

| Transport Package | Wooden Case |

| Specification | 6.2x 3.1 x 1.87m |

| Trademark | Tinuo |

| Origin | Zhejiang, China |

| HS Code | 8422400090 |

Product Description

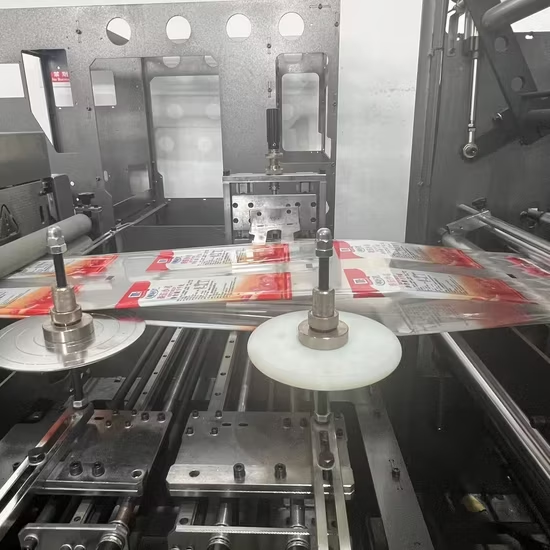

Fully Automatic Soft Loop Handle Bag Making Machine

This machine has 2 functions (soft loop handle bag,die cut handle bag).

It is coupled with machinery, light, electronic and pneumatic.

Main Features:

1 Flexible soft loop handle and patch film feeding system, fully automatic

2 Pre-sealing knife heated on double sides and strong for fusing, to make the bags without deformation

3 The best quality side sealing knife of Italy, heated to high temperature not deformation

4 Newly designed sealing knife top lift and turn over system

5 It's designed by heating punching and it's easy to cut off, the waster is excluded automatically

Optional devices:

1 Single sheet film unit, hydrulic device(connect or seperate)

2 Bottom seal knife + double seal knife

3 Top folding continuously device

Common unwind device

1 Unwinding adopt common loading, max diameter of raw rolling material is φ600mm

2 Adopt auto tension control

3 Unwinding with auto EPC

4 1600mm triangle folding device, which can adjustment

Top-folding continuously sealing device

1 The adjustable heat sealing available after top folding, seals top fold longitudinally and continuously, the width size of bag is not be limited

2 Inside heating wire sealing, which suit for full colours of bag

Soft loop handle bag device

1 Double layer unwinder

2 90 degree turnabout gear rotary soft loop

3 Special oblique drag style rotary soft loop

4 The whole type steel plate base, and special support bag structure

Collection Part

Technical parameter

Model | DC-800ZD | DC-800LP | DC-800SP | DC-800CSD | DC-800SDP |

| Length of bag-making(Height of bag) | 250-750mm | 250-750mm | 250-750mm | 250-700mm | 250-700mm |

Width of bag-making | 250-600mm | 250-600mm | 250-600mm | 250-600mm | 250-600mm |

Top-folding edge | 50-75mm | 50-75mm | 50-75mm | 50-75mm | 50-75mm |

Bottom gusset | 20-70mm | 20-70mm | 20-70mm | 20-60mm | 20-60mm |

Speed of bag-making | |||||

Soft loop handle bag | 60pcs/min | 60pcs/min | 120pcs/min | 100pcs/min | |

Patch handle bag | 60pcs/min | 60pcs/min | 100pcs/min | ||

Poly draw handle bag | 65pcs/min | ||||

Die cut handle bag | 80pcs/min | 80pcs/min | 80pcs/min | 140pcs/min | 120pcs/min |

Total power | 13KW | 10KW | 10KW | 10KW | 18KW |

Machine weight | 3500kg | 3200kg | 3200kg | 3000kg | 3600kg |

Machine dimension [L x W x H] | 8.2 x 3.1x1.87m | 6.2x 3.1 x 1.87m | 6 x 3.1 x 1.87m | 7x 2.2 x 1.95m | 10.2 x2.2x1.95m |

Air compressor [not included] | 7HP | 8HP | 8HP | 8HP | 75HP |

Machine Schematic

Bag Sample

Company Profile

In 2010, in response to global environmental protection and green packaging, we started open up a new field of non-woven machinery, becoming the first choice of customers. During the past many years, TINUO specializes in manufacturing non-woven bag making machines, paper bag machines, printing machines and different machines in packaging & printing industry. In 2020, we made timely adjustments to the challenges posed by the epidemic. Since 2021, we have constantly updated our products to make them more intelligent and environmentally friendly to provide the best quality, greenest and most cost-effective solutions for the whole packaging industry as well as each of our customers and always uphold the win-win cooperation concept.

Our Factory

We have a factory with a professional R&D team and production team to manufacture more advanced intelligent machines. In the production process of bag making machines, we pay attention to every detail and quality control of the production line. Our large investment technology allows us to produce parts that meet the exacting standard required to build a precision machines.

Our Advantage

1.China Top 3 packaging machinery Manufacturer2.We have 12 years of experience3.We have more than 80 patents4.We are willing and able to customize machines5.Our sales volume is the first place in the world

Our Certificate

Closely with international advanced technology production technology, TINUO has more than 80 patents, due to the changing of market demands, we willing and able to customize the machines. All production from us have passed ISO9001:2000, CE, B.V, SGS and GMC. With rich technology and capital resources, we pay high attention to the new product innovation.

Our Product

NON-WOVEN PACKAGE MAKING MACHINERY

PAPER PACKAGE MAKING MACHINERY

PLASTIC PACKAGE MAKING MACHINERY

PRINTING MACHINERY

LAMINATING MACHINES

SLITTING MACHINES

GENERAL PACKAGE MAKING MACHINERY

After sales service Q & A

--How to install the equipment?--Due the corona breakout in global, the seller would not arrange engineer outside to install, all the service would change to online service.--If the corona finished,how to install? And how long it will last?--The seller will send 1 engineer to install, test the machine and train customers' workers in buyers' factory.It will take about 1 week for the entire installation and training.--What are the additional costs of installation?

--The buyer should cover engineers' salary, visa cost, Round air tickets, accommodations, transportation in buyers' country, food, medical care, safety cost, and related cost happens in buyers' country. Also, the buyer should prepare enough labor, electric wire outside the control panel and tools for installations.

--What are the product warranty service terms?--Warranty period for the delivered equipment will be 12month after completion of erection but not later than 18months after shipment. In case any item proves to be defective and the damage is confirmed by seller's technicians within this period, the seller will at their choice either send engineer to repair or supply a new one for replacement free of charge on the basis of CNF delivery.

Welcome to contact us if you like our machine. thank you ! Try us an inquiry and you will not regret it !

Related Products

-

![Side Sealing Bag Making Machine]()

Side Sealing Bag Making Machine

-

![Eco Friendly Snack Instant Fried Noodles Disposable Paper Bowl/ Food Container Forming Making Machine Price for Hot Soup Salad Bowl Producing Machinery]()

Eco Friendly Snack Instant Fried Noodles Disposable Paper Bowl/ Food Container Forming Making Machine Price for Hot Soup Salad Bowl Producing Machinery

-

![Full Automatic Non Woven Shopping Bag Making Machine]()

Full Automatic Non Woven Shopping Bag Making Machine

-

![Maker Folder Flat Bottom Food Kraft Shopping Paper Bag Making Machine with Handle in Line]()

Maker Folder Flat Bottom Food Kraft Shopping Paper Bag Making Machine with Handle in Line